Good Vibes Only

Rubber-Metal Parts (NVH)

Find your febi replacement part at partsfinder

Selected Products

Good Vibes Only

with febi Rubber-Metal Parts (NVH)

The construction of modern chassis in automobiles is becoming increasingly complex. At the same time, owners of newer vehicle models also expect the best possible driving comfort, even on uneven roads.

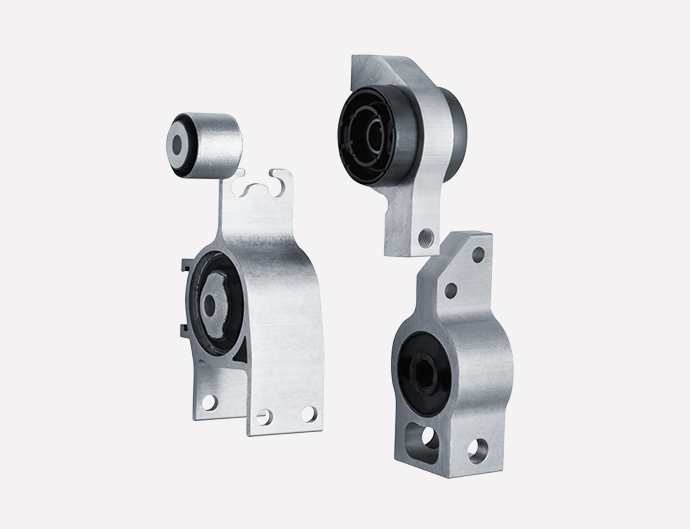

Thus, rubber to metal parts are becoming more and more important. They are especially used with multi-link axle constructions as elastic joints between chassis and body.

Rubber to metal parts absorb the vibrations of the road and drivetrain units that occur during driving and thus contribute significantly to increased driving comfort and sound insulation. In addition, they ensure driving safety by improving steering performance and driving stability when the road is uneven, as well as braking and avoiding manoeuvres.

febi offers one of the broadest ranges in the field of rubber to metal in the replacement parts market - of course, in tested OE-matching quality. The assortment ranges from various bearings such as suspension struts, cross-link and stabiliser bearings, through joint discs to motor bearings. With our many years of know-how, we can reliably meet the highest standards.

febi Rubber-Metal Components (NVH)

The Advantages at a Glance

Optimal processing for long life

High accuracy of fit

Strict quality standards

Rubber hardness complies with vehicle manufacturer specifications

Your No.1 for the reduction of Noise, Vibration and Harshness

- 8,000+ Mounts, Bushes and Dampers in range

- International coverage of up to 95% of all modern European and Asian passenger cars

- Range of Drivetrain Mounts covering a worldwide car parc of 260+ million passenger cars

- Range of Chassis Mounts covering a worldwide car parc of 350+ million passenger cars

- Always current applications in range with 500+ new articles per year

- OE-matching quality, tested and verified in-house

Noise, Vibration and Harshness

Noise is defined as an unpleasant or disruptive sound that causes some sort of disturbance, such as the rattling of a worn bearing.

Sound An operating part can create sound, which is related to its frequency of operation or mass, the higher the frequency, the higher the pitch. For example, the squeaking noise from a faulty suspension bush would be a high pitch sound compared with the low pitch droning noise from a failing wheel bearing.

Vibration is defined as the off-putting, repetitive motion of an object, such as a tyre out of balance which causes the steering wheel to oscillate at certain driven speeds.

Vehicle vibration consists of three elements, a source component, transfer path and a responding component. For example.

Source – Vibration from the engine.

Transfer path – Exhaust mountings.

Responding component – interior trim.

These vibrations which are caused by a failing or faulty part are sounds detected by humans using different senses, they are sometimes thought of as separate phenomena. This is incorrect, they are in fact the same. Sound waves are vibrations you are able to hear, whereas vibration is a sound you can feel. Both are measured in hertz.

Hertz (Hz)

Hertz is a unit of measure equal to the number of cycles completed in a second. A cycle can be described as an object moving from a rest state and returning back to rest. The number of times this cycle occurs in one second is the frequency, measured in hertz. Vibrations between 0-20 Hz are felt by humans. The vibrations between 20-200 Hz can be felt and heard, whilst vibrations between 200-20,000 Hz can only be heard, but not felt. Vibrations above 20,000 Hz are classed as ultrasonic, and are out of the range of a human ear.

Energy

Every object has a natural frequency, partly determined by its mass. Generally the larger the mass of an object, the lower the natural frequency that object has. When the frequency of a forced vibration on an object matches the natural frequency of that object, we experience resonance. Resonance occurs when an external force causes an object to oscillate with a greater amplitude at its specific natural frequency.

Harshness is more difficult to define as this is very subjective. However, it could be defined as a sudden, aggressive feeling, such as the response from the vehicle’s suspension when driving into a pothole.

Noise is defined as an unpleasant or disruptive sound that causes some sort of disturbance, such as the rattling of a worn bearing.

Sound An operating part can create sound, which is related to its frequency of operation or mass, the higher the frequency, the higher the pitch. For example, the squeaking noise from a faulty suspension bush would be a high pitch sound compared with the low pitch droning noise from a failing wheel bearing.

Vibration is defined as the off-putting, repetitive motion of an object, such as a tyre out of balance which causes the steering wheel to oscillate at certain driven speeds.

Vehicle vibration consists of three elements, a source component, transfer path and a responding component. For example.

Source – Vibration from the engine.

Transfer path – Exhaust mountings.

Responding component – interior trim.

These vibrations which are caused by a failing or faulty part are sounds detected by humans using different senses, they are sometimes thought of as separate phenomena. This is incorrect, they are in fact the same. Sound waves are vibrations you are able to hear, whereas vibration is a sound you can feel. Both are measured in hertz.

Hertz (Hz)

Hertz is a unit of measure equal to the number of cycles completed in a second. A cycle can be described as an object moving from a rest state and returning back to rest. The number of times this cycle occurs in one second is the frequency, measured in hertz. Vibrations between 0-20 Hz are felt by humans. The vibrations between 20-200 Hz can be felt and heard, whilst vibrations between 200-20,000 Hz can only be heard, but not felt. Vibrations above 20,000 Hz are classed as ultrasonic, and are out of the range of a human ear.

Energy

Every object has a natural frequency, partly determined by its mass. Generally the larger the mass of an object, the lower the natural frequency that object has. When the frequency of a forced vibration on an object matches the natural frequency of that object, we experience resonance. Resonance occurs when an external force causes an object to oscillate with a greater amplitude at its specific natural frequency.

Harshness is more difficult to define as this is very subjective. However, it could be defined as a sudden, aggressive feeling, such as the response from the vehicle’s suspension when driving into a pothole.

Countermeasures

by febi Vehicle manufacturers use a variety of Rubber to Metal based insulators to act as a countermeasure to vibration. The use of different types of rubber due to the properties of the elastomeric material determines which insulator is used to counteract the frequency, pitch and energy that is produced by each component.

When replacing any mounting or insulator, it is important to consider what it is made of, and how it is constructed, as these factors can dramatically affect the vehicles natural feel and driving behaviour. The stiffness or rigidity of an insulator affects the natural frequency. The stiffer the insulator means it would give a higher natural frequency, giving a more dynamic, but “harsh” feedback. The more flexible the insulator the lower natural frequency giving a more typical, “insulated” feedback.

Parts in Action

febi Chassis Mounts – for Greater Driving Safety, Comfort and Control.

Axle Beam Mounts

Vehicle design always evolves. The desire for non-intrusive suspension systems that do not impact on the vehicles interior require the use of a suspension subframe. These subframes are formed from tubular steel or aluminium and are mounted to the vehicles body using rubber-metal bushes.

- 400+ articles in range

- Covering 20,000+ European and Asian car applications

Strut Top Mounts

The suspension Strut Top Mounting is a bonded rubber bush, which is mounted to the top of the damper and fixed to the vehicles chassis. This is an integral part of the suspension strut assembly. Strut Mountings can also incorporate a bearing or a bearing plate which allows the strut to turn with the steered wheels.

- 700+ articles in range

- Covering 50,000+ European and Asian car applications

Control Arm Bushes / Hydro-Bushings

The elastomeric materials used in the production of rubber-metal parts are matched precisely to the technical requirements and loads of their specific fitting position. Despite all of this, passive rubbermetal components cannot absorb all of the vibrations within the chassis. As a result, hydraulically dampening elastomeric bearing “Hydromounts” were developed, which enable the isolating and dampening of vibrations.

- 1,200+ articles in range

- Covering 160,000+ European and Asian car applications

Drivetrain Mounts & Dampers

febi Drivetrain Mounts and Dampers are Absorbing Powertrain Vibrations.

Hydro Engine Mounts

Hydraulic Engine Mounts can adapt their characteristics depending on the induced load.

The viscous liquid in the Hydraulic Mount acts as a damper to ensure optimum insulation. Inside a Hydraulic Engine Mount, the main rubber spring has an upper and lower chamber. The chambers are connected by a series of canals and separated by a rubber valve.

- 1,200+ articles in range

- Covering 23,500+ European and Asian car applications

Transmission Mounts

The Transmission Mount controls the lateral movement of the drivetrain during acceleration and deceleration of the engine and transmission. The precise and controlled movement is critical, because if a Transmission Mounting is failing to control this movement, the selection of gears will feel imprecise. The use of quality materials of the exact construction is therefore vital for a Transmission Mountings correct operation.

- 1,900+ articles in range

- Covering 120,000+ European and Asian car applications

Decoupled Pulleys (TVD)

The power impulses of the engine result in torsional vibration in the crankshaft, which as a result starts twisting back and forth at a high frequency, especially at low engine speed. Without a damping effect, the vibration would be transmitted through the accessory belt drive system and could lead to premature component failure.

- 350+ articles in range Covering

- 14,000+ European and Asian car applications

Anti-Roll Bar Bushes

The Anti-Roll Bar is mounted on the vehicles subframe or chassis by the means of two bushes. The positive connection of the bonded rubber bushes prevents relative movements between the anti-roll bar and the bonded rubber bush. The rotational movements of the anti-roll bar are absorbed in the mounting, as the vehicle is being driven on a wide variety of road surfaces. Achieving a high degree of efficiency to reduce NVH and increased driver comfort.

- 1,000+ articles in range

- Covering 34,000+ European and Asian car applications

Flexible Discs

The design of Flexible Discs is used to absorb impact and shock forces to reduce drivetrain disturbances and prevent angular misalignment. Torque from the drivetrain is transmitted through loop packages made from special textile fibres using unique Tenpu® technology, which are then embedded in vulcanised rubber. This greatly reduces noise, vibration and harshness from the drivetrain and ensures maximum driver and passenger comfort.

- 100+ articles in range

- Covering 22,000+ European and Asian car applications

Good Vibes Only – with febi Rubber-Metal Parts

Hydro Bearings for Premium Models

The rubber components in rubber-to-metal parts cannot absorb all vibrations in the chassis. Therefore, hydraulically dampening elastomer bearings (hydro bearings) have been developed which consist of a metallic outer sleeve into which a specially shaped rubber material with fluid chambers and flow channels is embedded.

Due to the damping properties of the liquid occurring in addition to the rubber core, the optimum oscillation reduction is thus achieved even in higher frequency ranges with smaller amplitudes. Hydro bearings are mainly used in the models of premium vehicle builders.

febi offers a wide range of hydraulic bearings for various European vehicle brands and models — of course, in tested OE-matching quality.

Get the febi Newsletter