Quality from Start to Finish

Fuel & Exhaust System

Find your febi Truck replacement part at partsfinder

Selected Products

Quality from Start to Finish

The fuel system supplies the combustion chamber of the engine with the precise amount of diesel required at any given load.

febi’s expansive range includes a variety of different spare parts for the fuel and exhaust system, including: fuel pumps, feed pumps, exhaust manifolds, turbochargers, exhaust pressure sensors, exhaust temperature sensors and NOx sensors.

Your Benefits

Highest Quality

Strict quality standards of febi exhaust parts ensure that legal emissions standards are always met.

Precision Fit

Easy assembly thanks to perfect accuracy of fit.

Efficiency

Long service life with low wear.

The Greenkeeper of Giants

febi NOx Sensor

febi offers an expanding product program of high-quality NOx sensors as well as replacement parts for SCR systems including AdBlue® tank caps, urea filters and exhaust gas temperature sensors.

- Excellent resistance to environmental contamination, water, corrosion and operating fluids of the vehicle

- Electronics are sealed with silicone-based potting adhesive meeting the Class IP67 standard for excellent resistance to vibrations and temperature fluxuations

- Consistent design for durability and regular inspections for micro-cracks during the production process

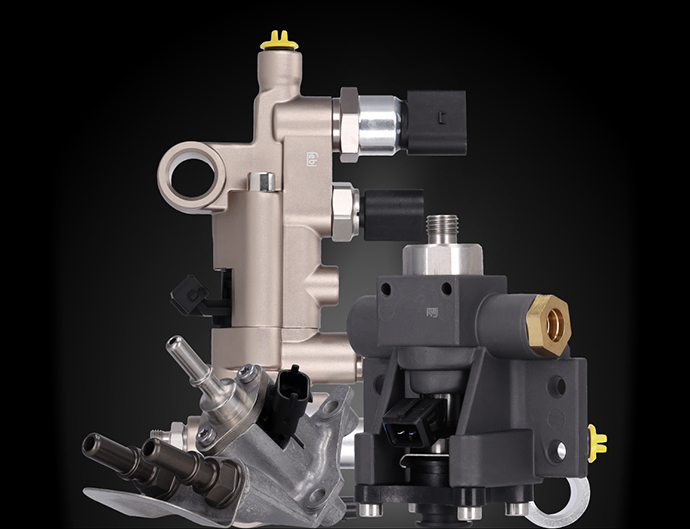

AdBlue® Dosing Modules

Dosage modules play an important role in SCR systems for reducing Nitrogen Oxide emissions, They ensure precise metering of the urea-water solution required for the reduction process, also known as AdBlue®, managing its atomisation and distribution in the exhaust pipe.

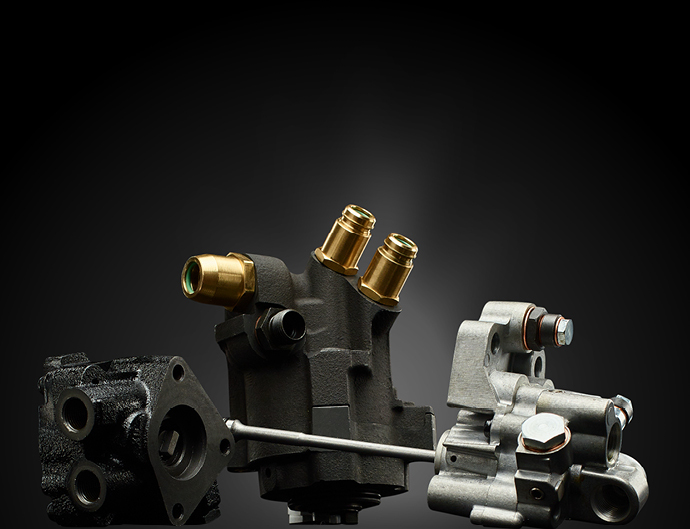

EGR Valves

Exhaust gas purification systems – such as SCR or EGR – are necessary for commercial vehicles to comply with current emissions legislation. However, EGR systems in particular are prone to failure.

Get the febi Newsletter