Find your febi replacement part at partsfinder

Selected Products

Focus Feature: Air Suspension

febi Air Suspension

Return to Original Comfort

Able to adapt to varying loads and road conditions, air suspension systems provide a smooth and customisable ride. Whether you seek luxury or a moment of quiet, febi ensures a safe and serene driving experience - just like the Original Comfort.

Initially used in trucks and buses for better comfort, handling and load management, air suspension soon became a feature on premium models from Mercedes-Benz, Audi, BMW and Land Rover. Today, an ever-increasing list of manufacturers offer vehicles equipped with Air Suspension.

febi Air Suspension Components are the Smartest Way to Return to Original Comfort!

For those seeking the best in Air Suspension performance and reliability, febi is your No. 1 choice for OE-matching replacement parts, ensuring your vehicle maintains its premium ride quality for years to come.

Watch animation & restore comfort

Your Benefits

New Range

febi is offering a new range of air springs struts, air springs and compressors with more than 100 articles for popular vehicles. These articles cover over 4,000 applications and a large number of vehicles on the road today.

High Quality

All febi Air Suspension articles are designed, specified and manufactured to ensure that they meet the high-quality standards of the bilstein group and OE-Matching quality and functionality.

Range Extension

Based on customer and market demands, this range will be extended with hundreds of interesting new articles in the near future to ensure we provide the Right Parts, in the Right Place, at the Right Time.

Fit & Forget

All Air Suspension articles are manufactured to offer the highest degree of installation safety and durability, safeguarded by our 3-Year Manufacturer Guarantee.

febi Air Suspension –Uplift Your Business with Original Comfort

- Increased Market Demand for New Air Suspension Parts

As Air Suspension expands beyond luxury vehicles into mainstream models, demand for OE-matching replacement parts is soaring. febi offers wholesalers the chance to tap into this growing market and significantly boost revenue. - OE-Matching Products – with Aftermarket Advantages

febi's Air Suspension parts are developed to meet OE standards, providing reliable, high-quality solutions that ensure workshop satisfaction and repeat business. - A Wide and Expanding Range

With coverage for everything from luxury saloons to SUVs and electric vehicles, febi’s range is always evolving to meet market needs. New parts, like Air Springs Struts and Compressors, will be added as we develop the range. - An Established Industry Leader

febi's standing as your No. 1 brand in the Independent Aftermarket (IAM) strengthens its appeal for wholesalers, helping them improve their market position with a well-known and established brand.

Return to Original Comfort –with Aftermarket Advantages

- The Best of Both Worlds

febi Air Suspension restores the smooth, reliable ride your customers expect all while offering great value. Our OE-matching parts deliver top-quality performance, allowing workshops to provide the best of both worlds: premium comfort and cost-effective solutions. - Premium Quality for the IAM

febi’s Air Suspension parts provide OE-level performance, offering workshops the opportunity to deliver exceptional quality and reliability while maintaining attractive aftermarket pricing. - Enhanced Customer Satisfaction

With adjustable ride quality for various road conditions, febi’s Air Suspension restores smooth, comfortable journeys, making it the perfect solution for both luxury and mid-range vehicles.

febi Air Suspension –Uplift Your Business with Original Comfort

- Increased Market Demand for New Air Suspension Parts

As Air Suspension expands beyond luxury vehicles into mainstream models, demand for OE-matching replacement parts is soaring. febi offers wholesalers the chance to tap into this growing market and significantly boost revenue. - OE-Matching Products – with Aftermarket Advantages

febi's Air Suspension parts are developed to meet OE standards, providing reliable, high-quality solutions that ensure workshop satisfaction and repeat business. - A Wide and Expanding Range

With coverage for everything from luxury saloons to SUVs and electric vehicles, febi’s range is always evolving to meet market needs. New parts, like Air Springs Struts and Compressors, will be added as we develop the range. - An Established Industry Leader

febi's standing as your No. 1 brand in the Independent Aftermarket (IAM) strengthens its appeal for wholesalers, helping them improve their market position with a well-known and established brand.

Return to Original Comfort –with Aftermarket Advantages

- The Best of Both Worlds

febi Air Suspension restores the smooth, reliable ride your customers expect all while offering great value. Our OE-matching parts deliver top-quality performance, allowing workshops to provide the best of both worlds: premium comfort and cost-effective solutions. - Premium Quality for the IAM

febi’s Air Suspension parts provide OE-level performance, offering workshops the opportunity to deliver exceptional quality and reliability while maintaining attractive aftermarket pricing. - Enhanced Customer Satisfaction

With adjustable ride quality for various road conditions, febi’s Air Suspension restores smooth, comfortable journeys, making it the perfect solution for both luxury and mid-range vehicles.

Benefits at a Glance

Your No. 1 for Steering & Suspension

Quality by Conviction

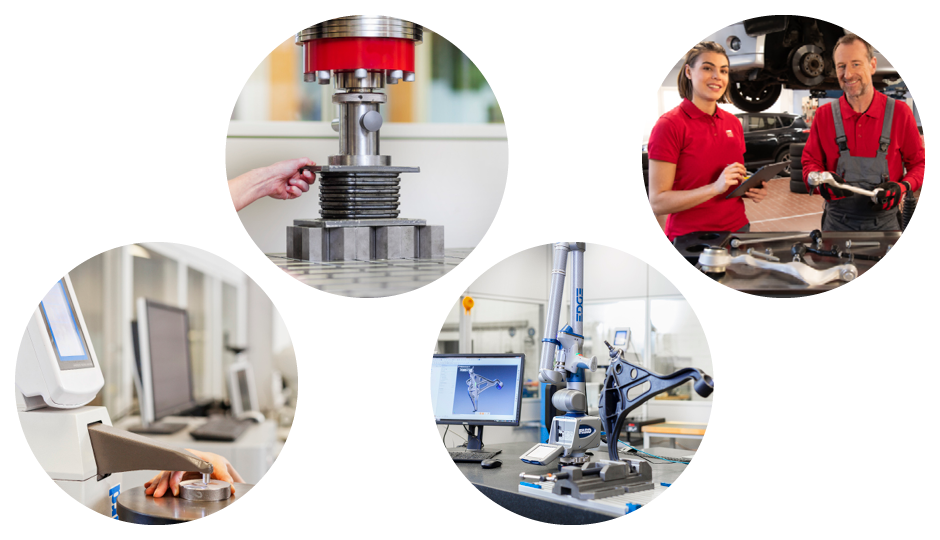

Care at Every Step of the Process

One of febi’s greatest strengths is reliability. This is ensured both with punctual product delivery and, above all, consistent product quality. At the same time, constant quality standards apply, which are assured with comprehensive, repeatedly performed product checks – from initial sample tests through to detailed incoming goods inspections.

These continuously challenge and reconfirm the claim of OE-matching quality asserted for every steering and suspension component. Steering and suspension parts from febi comply precisely with the product standards of the respective original equipment suppliers, making us your strong partner in the Independent Aftermarket.

Example traverse control arm: The product range exclusively includes traverse control arms that ensure 100% driving stability.

That is why our certified quality management tests the offered traverse control arms for different requirements and loads.

These include precision fit, dimensional stability, material quality, tensile strength and hardness.

Manufacturing Competence

We have a very long heritage in the metal processing industry dating back to 1844.

As a result, our in-house manufacturing facility – bilstein group Engineering – manufacture hundreds of steering and suspension components for febi.

All components go through a stringent 3-stage inspection process (against the OE equivalent) to ensure that they meet the high bilstein group quality standards.

Product Range

Steering & Suspension

febi is a byword for steering and suspension products that satisfy the highest demands of manufacturing quality and installation reliability.

We also set standards in terms of our programme: in the steering and suspension sector, febi provides one of the largest passenger car product ranges in the Independent Aftermarket – with more than 10,000 articles to cover all popular vehicle types.

With febi, you can be rest assured that we will always have the steering and suspension products for the latest vehicle generations on offer. Thanks to our dynamic new vehicle research process, we guarantee that we will always be fast to market.

Control Arms

An Alignment for Maximum Stability

The control arm is the mechanical link between the suspension strut and body and therefore is one of the most important functional components for passenger cars. At the same time, control arms also ensure correct wheel alignment. They hold the suspension strut in position and absorb forces in longitudinal and transverse directions during acceleration, deceleration and cornering.

Since the control arm is a safety-relevant wear part that sooner or later has to be replaced on every passenger car, this component is subjected to very exacting tests, especially by the TÜV (German Association for Technical Inspection). In these examinations, the control arm is one of the most frequently faulted parts.

Control arms from febi are characterised by precise workmanship, high-grade materials and use high-quality ball joints and bearings with the correct rubber hardness.

With a common alignment and a range of over 1,650 control arms in OE matching quality, febi offers maximum stability for the road, in the repair shop and in business.

Ball Joints

Safety and Quality Combined

The supporting ball joint connects the control arm to the suspension strut. The main task of the ball joint is to support the steering knuckle and to hold the widely-used McPherson strut in position at the base. As a safety-relevant component, the ball joint must absorb the forces exerted during braking, acceleration and cornering.

A defective component makes its presence felt with clicking or knocking noises from the front axle. The major cause of failure are the protective rubber boots that allow dirt and moisture to enter the joint. This leads to corrosion and ultimately to play in the joint. It can also result in imprecise steering and an unevenly worn tyre tread pattern. When replacing the ball joint, attention must always be paid to ensuring that the surrounding components, such as the axle boot, are not damaged. After replacement, the need may arise for wheel alignment, which must be conducted according to the manufacturer specifications.

febi makes an important contribution to road safety with up to 500 high-quality ball joints ensuring customers can always rely upon our products.

Tie Rods

Perfect Connection Guaranteed

Tie rods connect the steering gear to the crossmembers of the front wheels and ensure that both wheels turn together and maintain a specific angle relative to each other.

Changing the tie rod is necessitated by wear of the tie rod end or inner tie rod end (if these components are not available separately). Another reason could be deformation of the tie rod caused by shocks such as driving over potholes, excessive kerb contact, or an accident.

The functional dimension, i.e. the required length, of high-quality febi tie rods corresponds precisely to the original. If the length differs from that specified by the vehicle manufacturer, problems could arise during wheel alignment.

febi tie rods guarantee a perfect connection in the steering and suspension area. febi also guarantees this perfect connection in its everyday cooperation with you. With over 450 articles in its tie rod range, febi is the leader in the Independent Automotive Aftermarket.

Tie Rod Ends

Precise Control of Your Destination

The outer tie rod end transfers the movement from the steering wheel to the wheels and allows the wheels to move relative to the vertical axis. In order to be effective, the steering system has to turn the wheels at the same rate and along the same plane in any condition of both the car and the road. A worn tie rod end can result to abnormal wear patterns on the tyres and erratic steering feel.

The rubber boot is vitally important for a long service life: in order to avoid corrosion and play in the joint, febi only uses the highest quality Chlorophene rubber. The correct material hardness of the mating surface with the crossmember is ensured by our certified quality management system.

febi provides an extensive range of more than 850 OE-matching quality tie rod ends for precise vehicle control – ensuring your customers always arrive safely at their destination.

Inner Tie Rods

Always on Track

The tie rod consists of an inner tie rod and a tie rod end. The inner tie rod is connected to the steering. The main function of this part is to convey the steering motion to the wheels. This keeps the vehicle in the right lane.

A typical sign of wear is play in the ball joint. This can occur, for example, if the plastic shell of the ball socket is worn.

One frequent reason for this unequivocal defect is repeated and excessively hard mounting of kerbs. As a pioneer in the Independent Automotive Aftermarket, febi and its inner tie rods ensure that repair shops and the trade always keep on track. With over 550 articles in range and coverage of 97% of popular vehicle types, febi leads the way.

Stabiliser Links

The Basis for Optimal Dynamics

The stabiliser link – also referred to as a sway bar link – is an important component for the driving dynamics of a passenger car. It connects the stabiliser bar to the body and as a part of the suspension, stabilises the vehicle especially when cornering by reducing roll, i.e. the tilting of the body structure towards the outside of the curve.

If knocking noises can be heard on uneven road surfaces from the front axle area, this could be a sign of a defective stabiliser link. It can usually be replaced without much effort and subsequent wheel alignment is normally not required.

As well as improving vehicle dynamics, it also optimises dynamics within the workshop. febi provides the basis for this with more than 1,000 vehicle-specific stabiliser links that are mostly available as complete repair sets and ProKits.

Product Range

Steering & Suspension

febi is a byword for steering and suspension products that satisfy the highest demands of manufacturing quality and installation reliability.

We also set standards in terms of our programme: in the steering and suspension sector, febi provides one of the largest passenger car product ranges in the Independent Aftermarket – with more than 10,000 articles to cover all popular vehicle types.

With febi, you can be rest assured that we will always have the steering and suspension products for the latest vehicle generations on offer. Thanks to our dynamic new vehicle research process, we guarantee that we will always be fast to market.

Control Arms

An Alignment for Maximum Stability

The control arm is the mechanical link between the suspension strut and body and therefore is one of the most important functional components for passenger cars. At the same time, control arms also ensure correct wheel alignment. They hold the suspension strut in position and absorb forces in longitudinal and transverse directions during acceleration, deceleration and cornering.

Since the control arm is a safety-relevant wear part that sooner or later has to be replaced on every passenger car, this component is subjected to very exacting tests, especially by the TÜV (German Association for Technical Inspection). In these examinations, the control arm is one of the most frequently faulted parts.

Control arms from febi are characterised by precise workmanship, high-grade materials and use high-quality ball joints and bearings with the correct rubber hardness.

With a common alignment and a range of over 1,650 control arms in OE matching quality, febi offers maximum stability for the road, in the repair shop and in business.

Ball Joints

Safety and Quality Combined

The supporting ball joint connects the control arm to the suspension strut. The main task of the ball joint is to support the steering knuckle and to hold the widely-used McPherson strut in position at the base. As a safety-relevant component, the ball joint must absorb the forces exerted during braking, acceleration and cornering.

A defective component makes its presence felt with clicking or knocking noises from the front axle. The major cause of failure are the protective rubber boots that allow dirt and moisture to enter the joint. This leads to corrosion and ultimately to play in the joint. It can also result in imprecise steering and an unevenly worn tyre tread pattern. When replacing the ball joint, attention must always be paid to ensuring that the surrounding components, such as the axle boot, are not damaged. After replacement, the need may arise for wheel alignment, which must be conducted according to the manufacturer specifications.

febi makes an important contribution to road safety with up to 500 high-quality ball joints ensuring customers can always rely upon our products.

Tie Rods

Perfect Connection Guaranteed

Tie rods connect the steering gear to the crossmembers of the front wheels and ensure that both wheels turn together and maintain a specific angle relative to each other.

Changing the tie rod is necessitated by wear of the tie rod end or inner tie rod end (if these components are not available separately). Another reason could be deformation of the tie rod caused by shocks such as driving over potholes, excessive kerb contact, or an accident.

The functional dimension, i.e. the required length, of high-quality febi tie rods corresponds precisely to the original. If the length differs from that specified by the vehicle manufacturer, problems could arise during wheel alignment.

febi tie rods guarantee a perfect connection in the steering and suspension area. febi also guarantees this perfect connection in its everyday cooperation with you. With over 450 articles in its tie rod range, febi is the leader in the Independent Automotive Aftermarket.

Tie Rod Ends

Precise Control of Your Destination

The outer tie rod end transfers the movement from the steering wheel to the wheels and allows the wheels to move relative to the vertical axis. In order to be effective, the steering system has to turn the wheels at the same rate and along the same plane in any condition of both the car and the road. A worn tie rod end can result to abnormal wear patterns on the tyres and erratic steering feel.

The rubber boot is vitally important for a long service life: in order to avoid corrosion and play in the joint, febi only uses the highest quality Chlorophene rubber. The correct material hardness of the mating surface with the crossmember is ensured by our certified quality management system.

febi provides an extensive range of more than 850 OE-matching quality tie rod ends for precise vehicle control – ensuring your customers always arrive safely at their destination.

Inner Tie Rods

Always on Track

The tie rod consists of an inner tie rod and a tie rod end. The inner tie rod is connected to the steering. The main function of this part is to convey the steering motion to the wheels. This keeps the vehicle in the right lane.

A typical sign of wear is play in the ball joint. This can occur, for example, if the plastic shell of the ball socket is worn.

One frequent reason for this unequivocal defect is repeated and excessively hard mounting of kerbs. As a pioneer in the Independent Automotive Aftermarket, febi and its inner tie rods ensure that repair shops and the trade always keep on track. With over 550 articles in range and coverage of 97% of popular vehicle types, febi leads the way.

Stabiliser Links

The Basis for Optimal Dynamics

The stabiliser link – also referred to as a sway bar link – is an important component for the driving dynamics of a passenger car. It connects the stabiliser bar to the body and as a part of the suspension, stabilises the vehicle especially when cornering by reducing roll, i.e. the tilting of the body structure towards the outside of the curve.

If knocking noises can be heard on uneven road surfaces from the front axle area, this could be a sign of a defective stabiliser link. It can usually be replaced without much effort and subsequent wheel alignment is normally not required.

As well as improving vehicle dynamics, it also optimises dynamics within the workshop. febi provides the basis for this with more than 1,000 vehicle-specific stabiliser links that are mostly available as complete repair sets and ProKits.

References of more than…

2150

Control Arms and Ball Joints

1300

Tie Rods and Tie Rod Ends

1450

Inner Tie Rods and Stabiliser Links

febi ProKit

Supplied complete. Repaired non-stop.

As an everyday workshop repair, it is often the case that not only the wear part, but also its fitting materials, need to be replaced. However, these additional articles – mostly nuts and bolts – are not often included with the individual replacement part.

With over 2,750 Steering and Suspension ProKits available, febi provides a remedy by offering appropriate assembly kits, particularly for steering and suspension components, which include all the necessary mounting parts (e.g. control arm bearings, mounting brackets, ball joints, spring lock washers, etc.) for quick and efficient repairs.

febi ProKit is the tailor-made total solution with which required repairs can be completed without delay.

febi ProKits for Steering and Suspension

Anti-Roll Bar | Axle Bearing | Stabiliser | Ball Joint | Stabiliser Link | Control Arm | Stabiliser Mount | Control Arm Mount | Strut Mount | Guide Link | Tie Rod | Integral Linkage | Tie Rod End

Anti-Roll Bar ProKits

Road debris, salt and other external factors are frequent causes of damage to the anti-roll bars‘ coating. When the bar is impaired, squeaking noises are a typical sign of wear. When the painting around the mounting points is harmed, the part will need replacing – as will the rubber mounts.

febi’s range of anti-roll bar ProKits are a tailor-made solution. We offer assembly kits which include all of the necessary mounting parts (e.g. bushes, stabiliser links, nuts, bolts and brackets) so that repairs can be completed without delay.

febi offers a market leading range of anti-roll bar ProKits manufactured in OE-matching quality for a wide range of popular vehicle makes and models.

This will save time and money for both the workshop and their customers!

Get the febi Newsletter