Hot Stuff, Cool Tech

Engine Thermal Management

Find your febi Truck replacement part at partsfinder

Selected Products

Hot Stuff, Cool Tech

febi Engine Thermal Management Parts

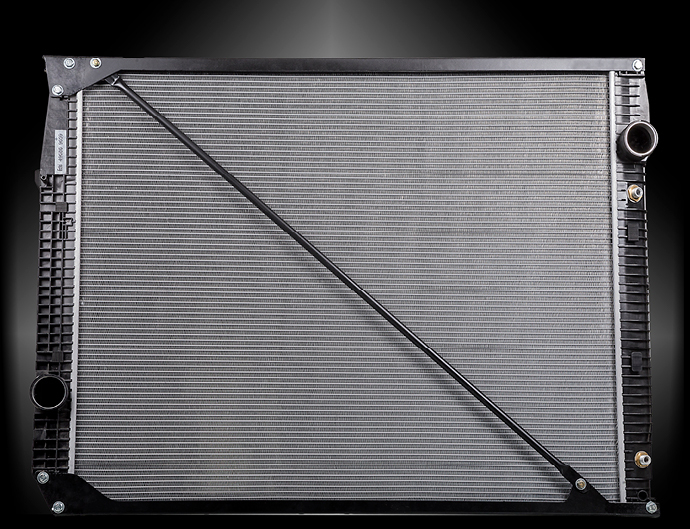

A combustion engine must operate within a certain temperature range in order to function efficiently and reliably.

In order to meet the modern day requirements for safety, comfort and economy, electronic components play a key role in virtually every aspect of a vehicle’s operation.

febi offers a comprehensive range of products in the field of engine thermal management, including: thermostats, fan couplings, cooling expansion tanks and water pumps, all – as always – in OE-matching quality.

Your Benefits

Longevity

Long service life.

Precision Fit

Manufactured to assure an absolute accuracy of fit.

Highest Quality

Designed with strict quality standards.

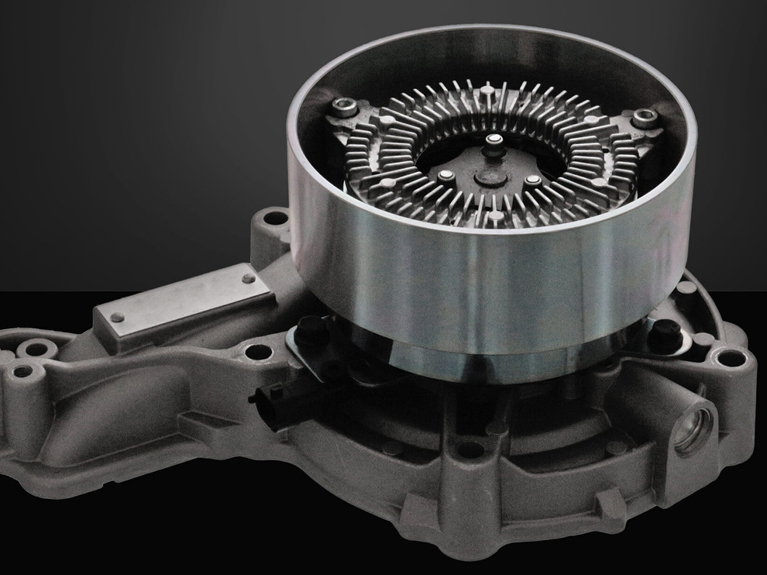

Switched Water Pumps

Efficiant Innovation

The use of a switched water pump can decrease fuel consumption by up to 1.5%, as well as help the vehicle meet Euro 5 and Euro 6 emission standards.

Engine Thermal Management at a Glance

High performance for a perfectly running engine

febi relies on its know-how as a manufacturer for this important product group.

Commercial water pumps are manufactured using the latest CNC machines in our own production facility located near febi headquarters in Ennepetal, Germany.

- Manufacturer competence – “Made by febi”

- Long service life thanks to use of high-quality components, such as slide seal rings from original equipment supplier KACO

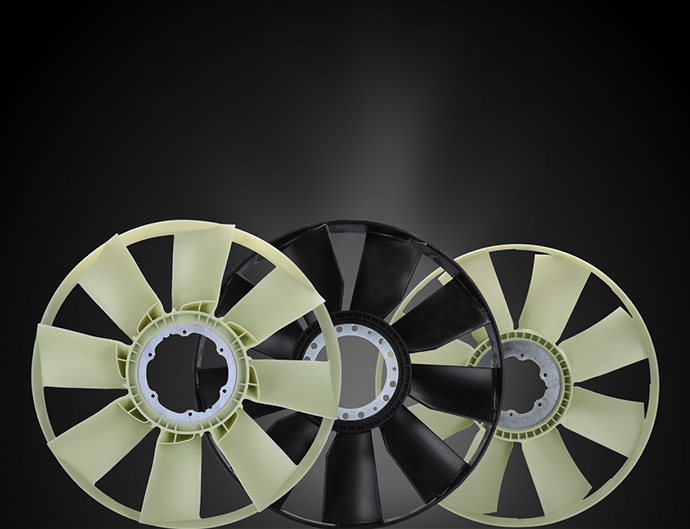

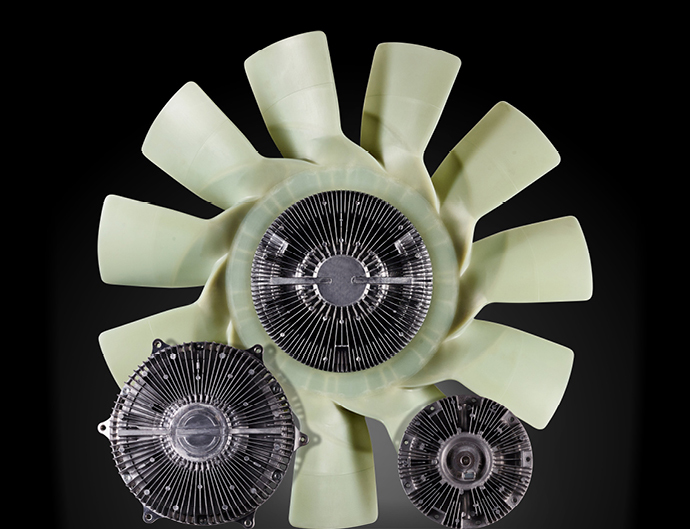

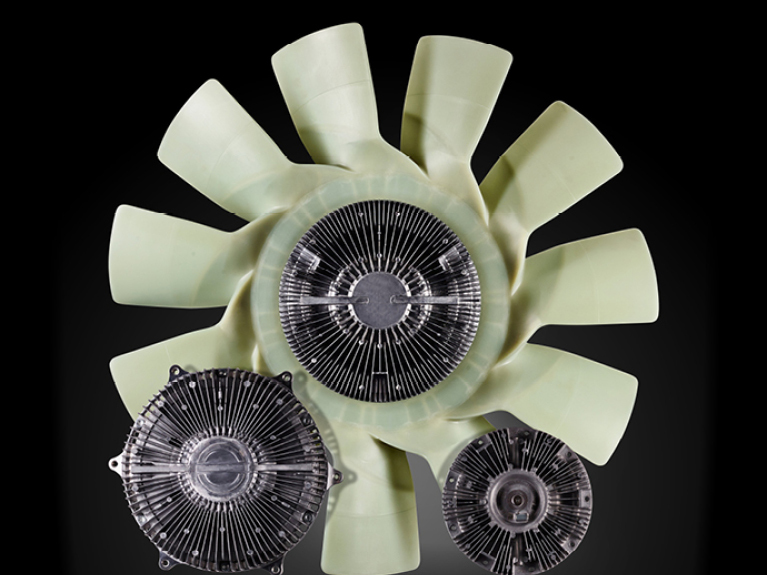

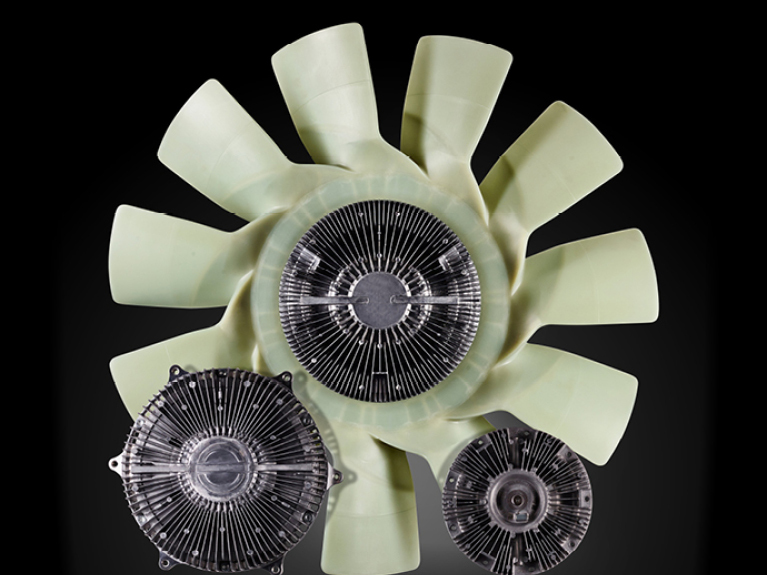

For fresh air

febi offers both non-electronically and electronically controlled fan coupling, the latter helping to save fuel and thus protect the environment.

- Authorised distribution partner of the OE-supplier BorgWarner Cooling Systems

- Fan blades balanced for vibration-free running

- Special material ensures reliable operation at extremely high and low temperatures

- For quick and efficient repairs, febi also supplies the fan coupling and fan blades individually

High performance for a perfectly running engine

febi relies on its know-how as a manufacturer for this important product group.

Commercial water pumps are manufactured using the latest CNC machines in our own production facility located near febi headquarters in Ennepetal, Germany.

- Manufacturer competence – “Made by febi”

- Long service life thanks to use of high-quality components, such as slide seal rings from original equipment supplier KACO

For fresh air

febi offers both non-electronically and electronically controlled fan coupling, the latter helping to save fuel and thus protect the environment.

- Authorised distribution partner of the OE-supplier BorgWarner Cooling Systems

- Fan blades balanced for vibration-free running

- Special material ensures reliable operation at extremely high and low temperatures

- For quick and efficient repairs, febi also supplies the fan coupling and fan blades individually

Get the febi Newsletter