Consistent Quality. Full Stop!

Braking

Find your febi Truck replacement part at partsfinder

Selected Products

Consistent Quality. Full Stop!

febi Braking

When a truck driver slams on the brakes several tonnes of weight must be stopped as quickly as possible. Put simply, a well-maintained and impeccably functionig braking system comprising high-quality components is absolutely vital.

febi exclusively offers commercial vehicle braking products in proven OE-matching quality. Safety is always the focus; our internal quality control tests all brake components for various requirements and loads. This is how we contribute to road safety.

Your Benefits

Extensive Range

More than 730 braking components - 97% coverage for brake discs and pads, the highest in the Independent Aftermarket.

Premium Content

febi brake discs and pads match or exceed the ECE R90 regulation as required.

Made For the Road,

Tested On the Race Track

Were febi parts up to the challenge of motorsport? There was only one way to find out. febi brake parts were installed on a racing truck and put through their paces at the demanding 4.2 KM Autodrom Most circuit in the Czech Republic - the ultimate test, and one our products passed with a perfect score!

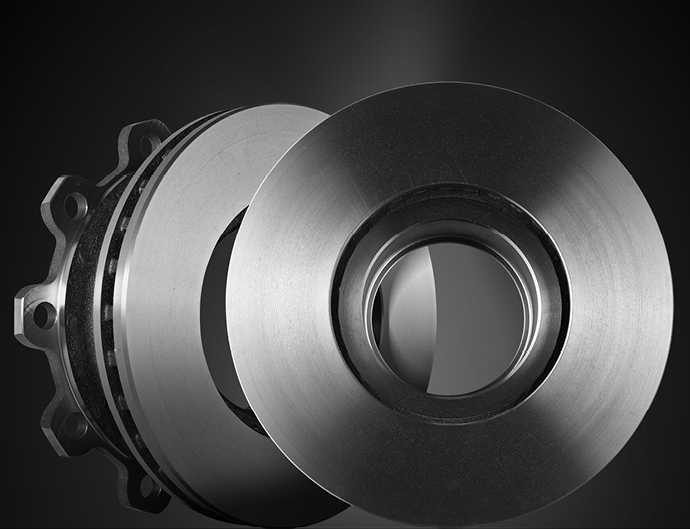

The febi Brake Disc:

The Experiences of Truck Racing Experts

The complete range

for the commercial vehicle brake system

Slack Adjusters

In commercial vehicle air brake systems slack adjusters are used to compensate for the wear of brake linings and brake drums to provide consistent clearance between these components.

febi provides a wide range of slack adjusters for all common European commercial vehicles.

- Manufactured for long service life and safe operation even under the most demanding of conditions

- Suitable for heavy-duty use, even on unpaved roads and in harsh environments

- Precisely hardened worm gear reduces wear and improves long-term durability

Brake Camshaft

Flawless manufacturing with accurate dimensions of the splines – as well as the correct shape and hardness of the S-cam – is crucial not only for safety but a long service life too. febi offers brake camshafts carefully manufactured from premium-quality steel with exact fitting dimensions for secure and reliable operation.

Brake Shoe

Brake shoes have to be carefully manufactured to guarantee performance and durability. The radius of the brake lining carrier, the mounting bores and the shoe roller all must be produced within extremely fine tolerances. febi brake shoes are manufactured with specially hardened contact points for low wear and a long service life.

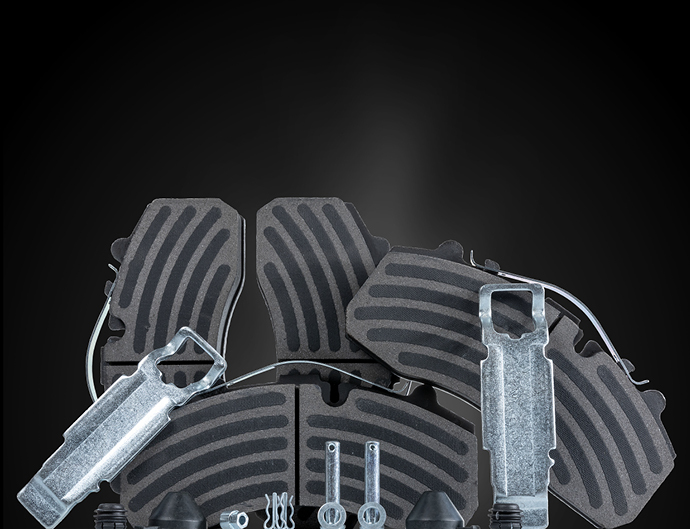

Caliper Repair Kits

In order to achieve maximum braking performance, the brake pad must move smoothly on the slider pins over the entire travel of the brake pads. Dirty or worn slider pins will adversely affect the braking performance. febi offers brake caliper Repair Kits for all common brake systems used on European commercial vehicles as a cost-effective alternative to replacing the complete caliper assembly.

Brake Chambers

febi offer a broad range of over 17 different brake chambers for all common trucks from European commercial vehicle manufacturers.

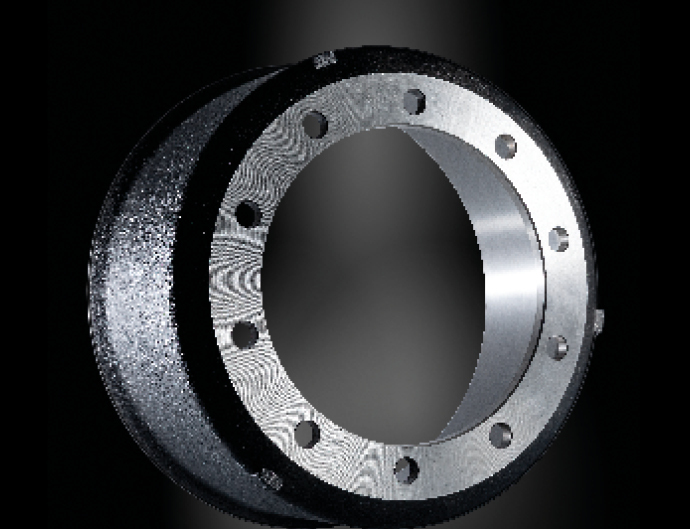

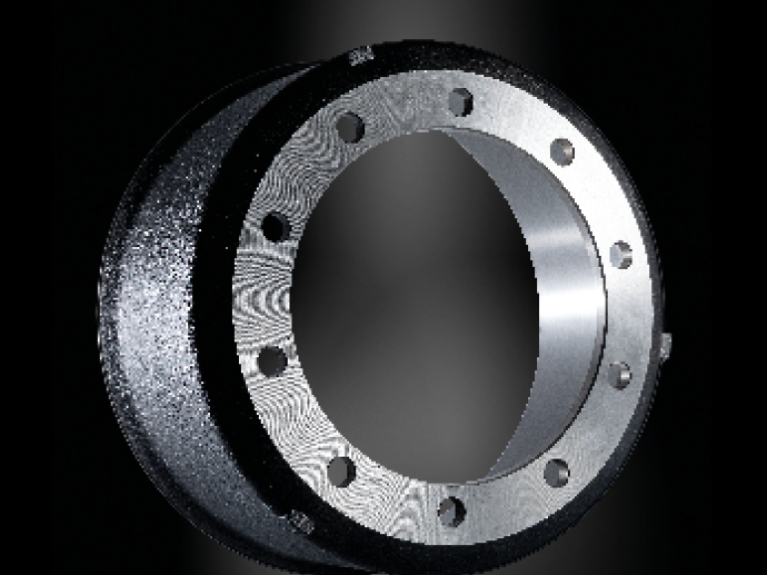

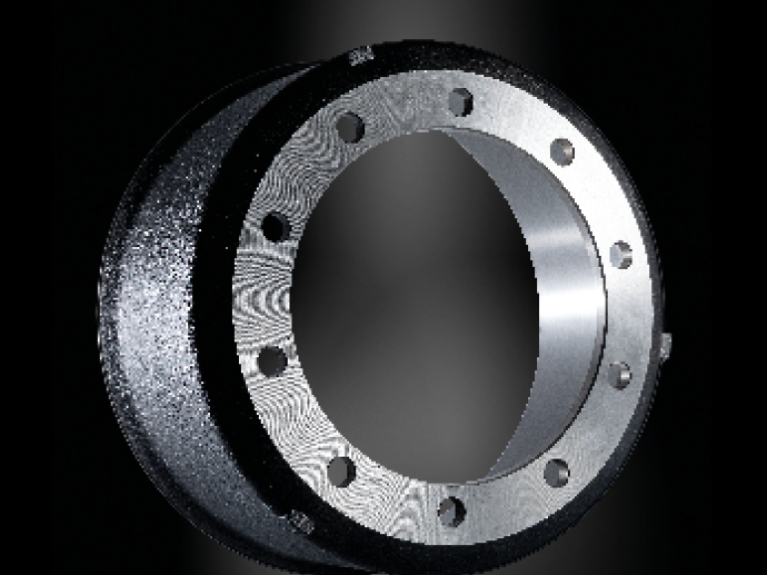

Brake Drums

As the biggest and one of the most important parts of the drum brake, the reliable function of the brake drum is crucial for safe driving. As the mechanical pressure and the heat caused by friction stresses the drum, only high-grade materials and precise manufacturing ensures dependability and a long service life.

febi brake drums are produced from high-grade grey cast iron to OE-matching quality with the right level of surface roughness, ensuring both excellent durability and a fast bedding-in process.

Wear Indicators

When brake pads reach their wear limit the warning contact embedded in the pad is activated, which in turns illuminates the warning indication light. This means the brake pads must be replaced.

febi offer a huge range of wear indicators for the different brake systems used in all common European commercial vehicles.

Slack Adjusters

In commercial vehicle air brake systems slack adjusters are used to compensate for the wear of brake linings and brake drums to provide consistent clearance between these components.

febi provides a wide range of slack adjusters for all common European commercial vehicles.

- Manufactured for long service life and safe operation even under the most demanding of conditions

- Suitable for heavy-duty use, even on unpaved roads and in harsh environments

- Precisely hardened worm gear reduces wear and improves long-term durability

Brake Camshaft

Flawless manufacturing with accurate dimensions of the splines – as well as the correct shape and hardness of the S-cam – is crucial not only for safety but a long service life too. febi offers brake camshafts carefully manufactured from premium-quality steel with exact fitting dimensions for secure and reliable operation.

Brake Shoe

Brake shoes have to be carefully manufactured to guarantee performance and durability. The radius of the brake lining carrier, the mounting bores and the shoe roller all must be produced within extremely fine tolerances. febi brake shoes are manufactured with specially hardened contact points for low wear and a long service life.

Caliper Repair Kits

In order to achieve maximum braking performance, the brake pad must move smoothly on the slider pins over the entire travel of the brake pads. Dirty or worn slider pins will adversely affect the braking performance. febi offers brake caliper Repair Kits for all common brake systems used on European commercial vehicles as a cost-effective alternative to replacing the complete caliper assembly.

Brake Chambers

febi offer a broad range of over 17 different brake chambers for all common trucks from European commercial vehicle manufacturers.

Brake Drums

As the biggest and one of the most important parts of the drum brake, the reliable function of the brake drum is crucial for safe driving. As the mechanical pressure and the heat caused by friction stresses the drum, only high-grade materials and precise manufacturing ensures dependability and a long service life.

febi brake drums are produced from high-grade grey cast iron to OE-matching quality with the right level of surface roughness, ensuring both excellent durability and a fast bedding-in process.

Wear Indicators

When brake pads reach their wear limit the warning contact embedded in the pad is activated, which in turns illuminates the warning indication light. This means the brake pads must be replaced.

febi offer a huge range of wear indicators for the different brake systems used in all common European commercial vehicles.

Watch our Slack Adjusters video

Get the febi Newsletter