Consistent Quality. Full Stop!

Braking

Find your febi replacement part at partsfinder

Selected Products

Consistent Quality. Full Stop!

febi Braking Parts

Your No.1 for Braking

When applying your brakes, every centimetre counts. For this reason, the febi braking range only consists of OE matching quality products to guarantee an unquestionable stopping performance in all driving conditions. Driver safety is always our top priority, which is why our certified Quality Management department stringently tests all brake components for various requirements and standards. We offer our customers a wide range of brake friction products - from discs and pads, to drums and shoes. With more than 2,750 components for popular vehicle applications, wholesalers and workshops will find everything they need with febi.

Constantly Growing Programme

We cover over 98% of all vehicles on European roads from the year 2000 onwards. In order to meet the market demands at any time and to be able to supply our customers with the replacement parts they need, we keep up-to-date with every new vehicle that is released into the market.

Our goal is clear: the perfect balance between performance, driving comfort and longevity. With this goal, febi is – and always will be – your No.1 for braking.

febi Braking Components

Your Benefits at a Glance

Broad braking range

Coverage of 98% of all popular European passenger cars for brake discs and brake pads

OE matching quality

All braking products combine performance, driving comfort and longevity

febi Brake Friction Promotional Video

The febi Manufacturer Guarantee

Our Quality Promise – Your Added Value

In order to underline our high product quality standards, we are providing a 3 year manufacturer's guarantee for all of our replacement parts – exceeding the statutory warranty.

How We Ensure Quality

The material quality of all components is crucial for the safe functioning of the braking system.

Brake discs must be uncompromisingly safe and durable to ensure a 100% braking effect under all driving conditions. For this reason every febi braking product goes through a comprehensive quality process.

How We Guarantee Our Quality

- Dynamometer tests, including checks for braking, noise and wear performance

- Physical and chemical tests for hardness, shear strength and compressibility

- Checked for brake fade, thermal conductivity and wear behaviour

- Extensive inspections of incoming goods through random sample testing

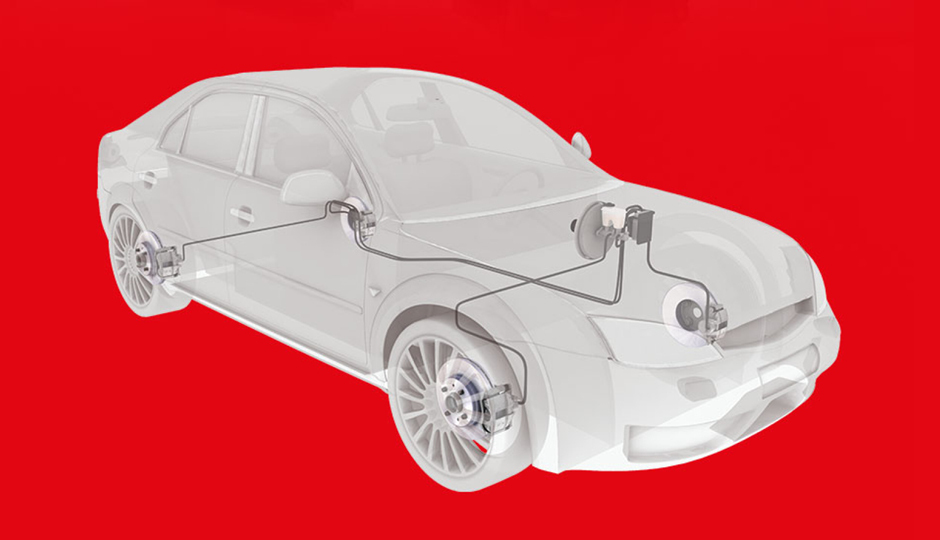

Braking System

Friction is Key

When braking and stopping a vehicle, kinetic energy is converted into thermal energy through friction. Friction refers to the resistant force that is generated when two moving objects make contact with each other e.g. the brake disc and pad.

When the driver presses onto the brake pedal, the power is increased by the brake servo and converted into hydraulic pressure by the master cylinder. The pressure delivered to the brake pad is approximately 30 times higher than the pressure that the driver applies to the brake pedal. With that in mind, if you apply a force of 15 kg to the brake pedal, you will generate a braking force of 450 kg.

Did you know?

When braking at 100 km/h, there is enough heat generated to boil two litres of water in three seconds.

Noise, Vibration and Harshness (NVH) in Braking

For Quiet, Effective Brakes

Minimising Vibrations and Noise

Rattling, vibrations, noise - all of these NVH sensations can spoil the driving experience. The noise noises and vibrations that the driver sometimes hears or feels when braking are amongst the most common.

During the development of a new febi brake pad, many technologies are used to minimise these unpleasant vibrations and noises in order to improve the comfort for both the driver and passenger/s.

All febi brake pads have the benefits and features of the OE part – sometimes even exceeding it - in order to minimise NVH e.g. chamfering and/or the addition of slots to ‘tune’ the pad so it makes less noise.

There are also a variety of shims that can be fitted to the steel backing plate to further dampen and absorb any vibrations between the brake pad and caliper.

Certain brake pads also come supplied with anti-rattle clips or springs that minimise ‘play’ between the pads and caliper to further dampen vibrations.

For quiet and effective braking, rely on the premium products from febi.

Brake Discs

Unwavering Precision

The brake disc rotates with the wheel. If the brake pedal is depressed, the brake pads are pressed against the brake disc by a piston in the brake caliper. The friction generated slows down the disc and thus the vehicle.

A substantial amount of heat is generated during the braking process. Long or aggressive braking can cause the temperature of the brake discs to rise so dramatically that they start to become less effective and fade.

As a result, high-quality febi brake discs are designed to dissipate heat quickly and effectively in the right areas. The precise weight, mass, density and the correct (high carbon composition) material are also crucial in the production process.

From Raw Materials to Precision Products

febi brake discs are manufactured to the highest standards using a grey iron smelting process combining new/recycled materials and metal composites. The result is a brake disc with high thermal efficiency and optimal damping properties, thus preventing vibrations and annoying noise.

Brake Pads

Reliable & Comfortable

febi brake pads are characterised by high shear strength, an excellent stability friction coefficient, low noise levels and minimal vibration. This is how we guarantee a safe and comfortable braking operation.

The Individual Components of a Brake Pad:

- Friction Material Features: Specially matched to the particular vehicle type and model

- Intermediate Layer Features: Optimised compressibility reduces heat transfer

- Adhesive Features: High shear strength; bonds friction material to the pad carrier

- Backing Plate Features: High material strength

- Shim Features: Reduces brake noise

How febi Brake Pads Perform:

- Long service life Optimal efficiency i.e. specified friction coefficient

- Stable effectiveness under various conditions of use

- Immune to environmental influences

- Mechanical strength and high temperature resistance

- Low wear of the friction material

- Low thermal conductivity

Drum Brakes

Traditional Stopping Power

Typically, drum brakes are used in the rear braking system of smaller passenger cars; they also have the proven ability to serve as a parking brake, which can be combined within a disc brake on some larger vehicles.

With this system, friction is generated by pressing the brake linings against the inside surfaces of the drums which rotate with the wheel. Thanks to this rotation, the brake shoes are pressed against the drum with greater force, thus slowing it down.

There are different types of drum brake designs subject to how the brake shoes are applied. The most common type used today on passenger cars is the leading/trailing type. The leading shoe is a term that refers to the shoe that moves in the direction of rotation when it is being pressed against the drum. The other shoe is called the trailing shoe, moving against the direction of rotation and is usually connected to the park braking cable.

Brake Calipers

High-Speed Replacement

A brake caliper is one of the main functional parts of the braking system. When operated, it uses hydraulic pressure to apply force to the back-plate of the brake pad, providing a clamping force for the friction material against the rotating brake disc.

Brake calipers can be repaired but this is a time-consuming job and will significantly increase the workshop labour time compared to the relative simplicity of changing a caliper. On average, it takes half the time to simply replace a caliper than to repair it.

febi’s brake calipers are completely new, with no remanufactured parts and no surcharge connected to the sales price. All febi brake calipers go through a rigorous inspection process to ensure that they are direct OE replacements and meet the high quality standards of the bilstein group.

febi brake calipers testing equipment:

- High/low pressure leakage testing

- High/low temperature testing

- Hydraulic performance testing

- Salt-spray testing

- Rubber parts projector inspection

- 3D-coordinate measuring

Take a look at our brake caliper animation

Braking Products for Hybrid and Electric Vehicles

Global emission laws are becoming increasingly strict and car companies are responding by providing new vehicle models that are either electric or hybrid. This is why febi also offers a wide range of brake pads and discs for these vehicles.

You can find the complete range here at

Other Braking Components in the febi Range

We cover over 98% of all vehicles on European roads from the year 2000 onwards. In order to meet the market demands at any time and to be able to supply our customers with the replacement parts they need, we keep up-to-date with every new vehicle that is released into the market.

Discover the full febi braking range at

Get the febi Newsletter