Excellent Under Pressure

Pneumatics

Find your febi Truck replacement part at partsfinder

Selected Products

Excellent Under Pressure

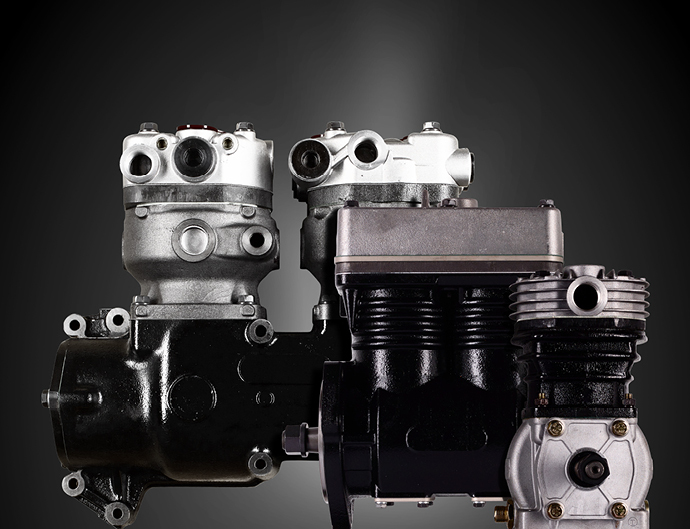

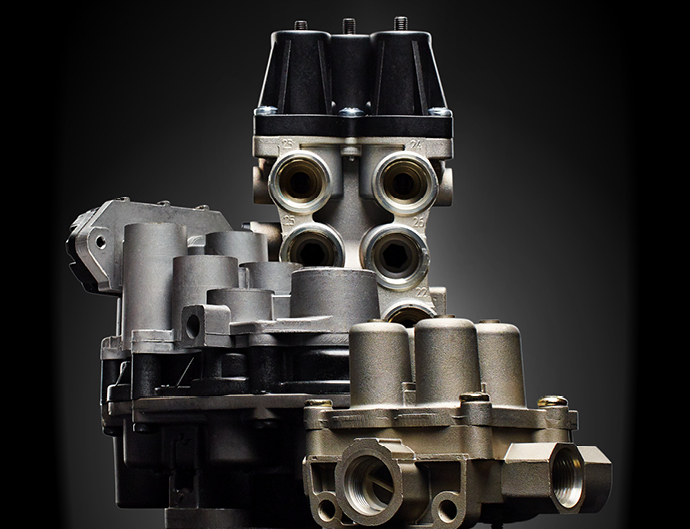

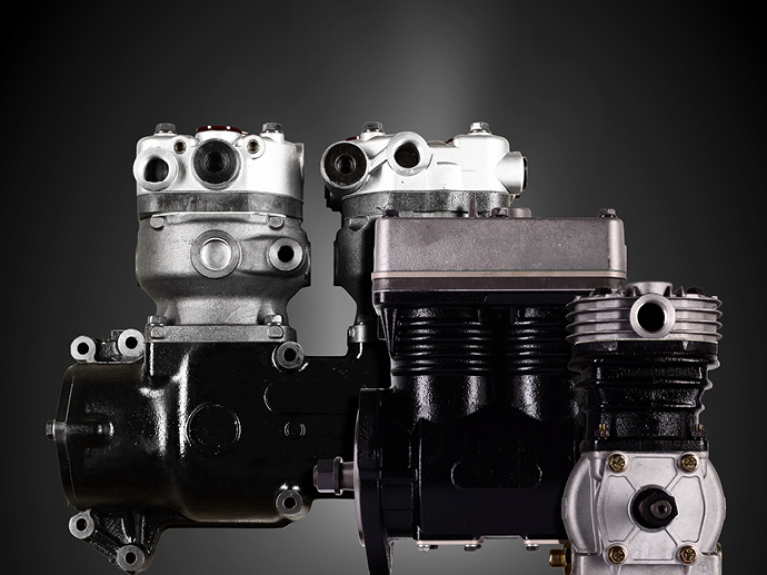

febi Pneumatic Parts

Many know the powerful hissing noise that emits from heavy goods vehicles, the cause of which being the hydraulic components that play a key role in how they operate.

febi offers a comprehensive assortment of replacement parts for the pneumatic systems fitted to European commercial vehicles, including: air-dryer cartridges, air compressors, clutch boosters, multi-circuit protection valves and air coils – all of course, as always, in tested OE-matching quality.

Your Benefits

Longevity

Excellent wear protection.

Highest Quality

Designed with strict quality standards.

Precise Fit

Manufactured to assure an absolute accuracy of fit.

Extended Air Tanks range for the ‘BIG 8’

Many important and safety-related systems in commercial vehicles are operated with compressed air, including the suspension, the transmission control and the brakes. febi Truck has expanded its range of air tanks. In order to guarantee the quality we are renown for, febi relies on a partnership with the OE-manufacturer, Frauenthal Automotive, the leading producer of air tanks.

Your Benefits

- Coverage of all common European brands and models of truck (the ‘BIG 8’)

- Use of premium materials and corrosion protection ensures long life and durability

- Ultra-high level of cleanliness inside the air tank prevents damage to sensitive components

- Matching mounting brackets, drain valves, compressed air connections and other accessories also available

The focus on internal cleanliness of febi Air Tanks prevents damage from dirt particles to the sensitive parts of the pressurized air system.

The service life and operational safety of febi Air Tanks exceeds the statutory requirements at least 200 times (*calculated according to the rules for simplified analysis for cyclic loading AD2000 S1).

No Chance for Corrosion

febi Air Dryer Cartridges

Workshops can rely on febi for quality parts when replacing air dryer cartridges. We offer a large selection of cartridges for numerous truck models – with or without an oil separator depending on the version.

- Wide range of air dryer cartridges for all common European brands and models of truck, trailer, bus and agricultural vehicle

- Highest material quality and optimal corrosion protection for safe operation and long life

- Available with or without oil separator for all applications

- Complete air dryer units are also available for many common vehicle types

Highest Quality for Exact Pressure

All pneumatic spare parts are thoroughly tested by febi.

Our stringent in-house quality management religiously tests all components at different requirements and loads, ensuring all febi pneumatic spare parts meet our extremely high standards.

Get the febi Newsletter