Perfectly Meshed

Engine Timing

Find your febi replacement part at partsfinder

Selected Products

Perfectly Meshed

with febi Timing Chain and Belt Kits

The engine is generally considered to be the heart of a vehicle.

Its design requires a balance between peak performance and torque, along with the lowest possible fuel consumption and low emissions. Modern engines are precision work — just as every single spare part from Ferdinand Bilstein.

In the field of engine management, we offer a comprehensive range of timing chains and belts for European passenger cars — of course, in tested OE-matching quality.

febi Engine Timing Components

Your Benefits at a Glance

OE – Compliance with vehicle manufacturer requirements.

Premium Content – by using OE suppliers, febi guarantees that the products inside the box are of the highest quality.

The Complete Solution – Premium packaging with better protection and product organisation.

Faster, Easier & More Accurate Item Identification

Leading Range – largest coverage in the Automotive Aftermarket, e.g. over 330 Timing Belt Kits cover upt to 90 % of all popular vehicles in Europe.

Repair Kits

Check of Surrounding Components

When replacing the timing chain or belt, the surrounding components should also be tested for wear.

In order for all parts to work together perfectly, it is extremely important that they are made accurately and from high-quality materials.

febi offers complete timing chains and belts for certain types of vehicles, which contain all the required parts for a professional exchange.

Timing Belts Engineered in Germany

Convincing in Every Aspect

Timing belts must meet the highest production standards as they perform an important function in the engine. In contrast to auxiliary belts, they are not frictionally engaged – but rather interlocked – which means that they must not slip under any circumstances. A slip could potentially lead to serious engine damage, which makes the quality of each individual timing belt even more important.

To guarantee the highest levels of product quality, febi sources its complete range of timing belts exclusively from selected OE suppliers – a large proportion of which are produced by a leading manufacturer from Germany.

Best Support for Every Customer

febi Timing Belt Repair Solutions

The customer is always our central focus, which is why we offer our belt drive products in various combinations to provide our customers with the best possible support.

You can choose from three different options:

- Individual Components – to optimise sales opportunities and offer an individual component repair

- Timing Belt Kit – for an economical repair solution, we offer kits without the water pump

- Timing Belt Kit with Water Pump – our recommended repair solution. This includes the water pump and all other required parts – all in one box

Simple but Clever:

All in One Box

Are unnecessary workshop visits generating additional costs? Are you missing key components that result in a delay to the complete repair? Are individually packed replacement parts taking up too many storage locations?

To ensure that our customers can work as time and cost-effectively as possible, we regularly analyse trends in the Independent Aftermarket and consistently develop new and supportive solutions.

Our timing belt kits with the water pump included contain all of the essential elements for a complete and professional repair. All in One Box!

Making OE-Matching Quality Timing Chain Kits available in the Automotive Aftermarket

One Brand, One Goal

Like all well-known OE manufacturers, febi uses only selected materials for the highest production quality, for example for our chain tensioner housings from in-house manufacturing that are mad of steel, die-cast aluminium or cast iron.

OE Matching Quality:

- 100% check of all timing chains and system parts

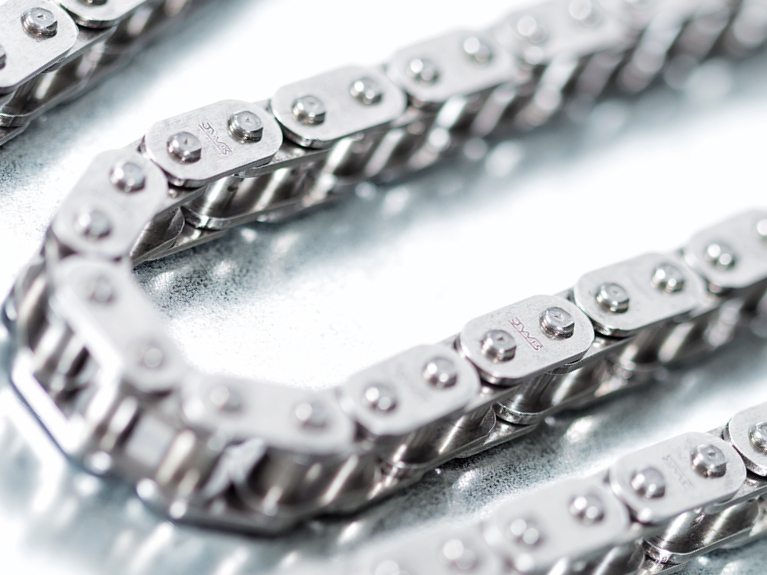

- Timing chains from OE manufacturer

- Timing chains with TRITAN®-coating

Production Expertise:

- Own production of important system parts, such as chain tensioners

- Technical training for workshops

Quality Assurance:

- Pinch, roll, tension and pressure checks through slug tests to test chain strength

- febi Timing Chain Kits come with a general manufacturer guarantee of 3 years.

All in one Box

Optimized Timing Chain Kits from febi

febi actively monitors developments and trends in the Independent Aftermarket to optimize its ranges.

The updated Timing Chain Kit programme provides a complete solution and a timely, cost-effective, professional repair in one box.

febi provides an extensive range of accurately catalogued Timing Chain Kits for all modern European and Asian passenger cars.

TRITAN®-Coating is the Solution!

Advantages of the TRITAN®-coating

- Wear reduction of at least 50% compared to conventional coating methods

- Approximately 20% less friction helps to reduce emissions

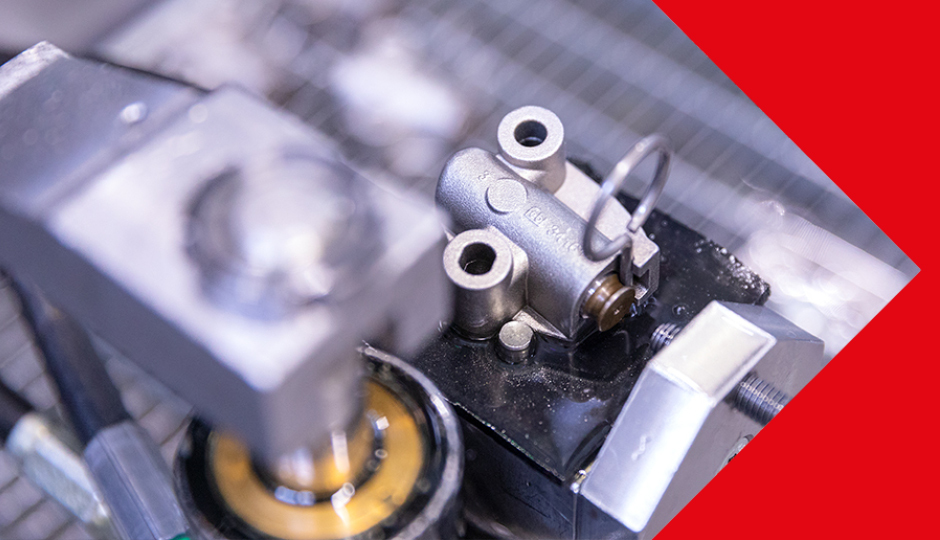

Chain Tensioners

Made in Germany

The task of the chain tensioner is to tension the timing chain in all operating conditions and to intercept unwanted vibrations even if wear elongation of the chain has occurred due to engine operation.

Quality is of enormous importance with this important component. This is why chain stretchers are precisely manufactured by bilstein group Engineering. Part of our chain stretchers are manufactured in our in-house production near the company headquaters in Germany on modern, CNC machines.

This ensures quality "Made in Germany".

Engine Timing Videos

Get the febi Newsletter