Find your febi Truck replacement part at partsfinder

Selected Products

Staying on Track

febi Steering & Suspension

The greatest challenge for modern, technologically advanced commercial vehicles is achieving the perfect balance between performance, economy, and environmental impact

All steering components are susceptible to regular wear and tear caused by the effects of mechanical stress and environmental conditions.

febi exclusively offers steering and suspension parts in tested OE-matching quality for maximum reliability, durability and safety.

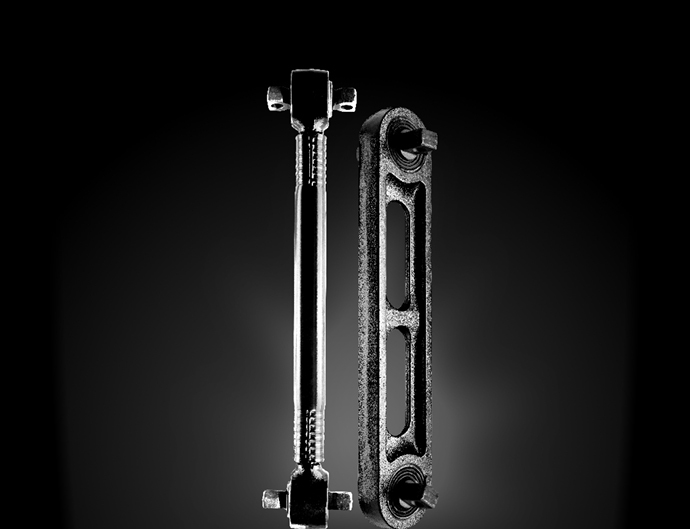

Focus Feature: King Pin Sets ‘Made in Germany’

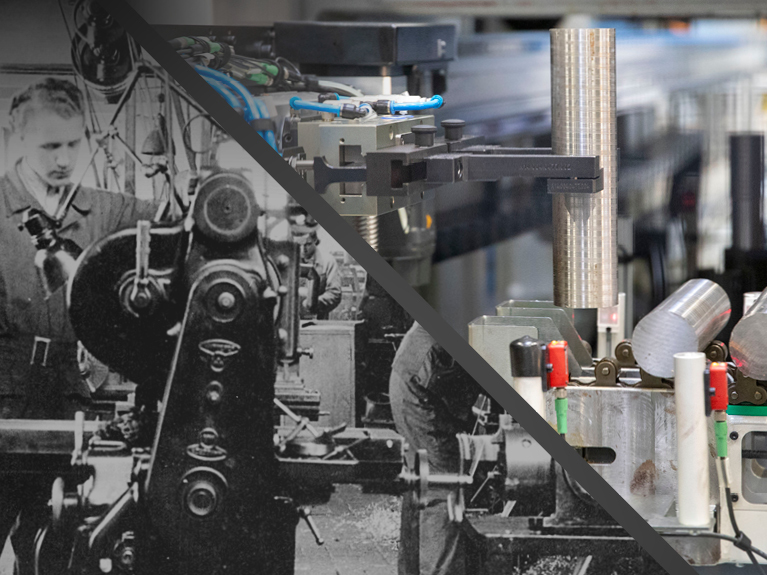

Leading the Way in King Pin Production

For over 40 years, we have been producing king pins in-house with precision and durability. By manufacturing at bilstein group Engineering in Germany, we maintain strict quality control and ensure superior performance. Reinforcing our dedication to in-house production, we have recently invested in a state-of-the-art CNC machining centre—guaranteeing consistent, OE-matching quality. Our components fully meet all requirements in accordance with OE specifications, including bearing tolerances (seats), hardness, and case depth, 100%.

As one of the few manufacturers in the IAM still prioritizing in-house king pin production, febi continues to lead the way—delivering trusted, high-quality solutions that keep commercial vehicles moving safely and reliably.

febi King Pin Sets –

Complete ProKits for Efficient Repairs

Most febi King Pin Sets come as ProKits—comprehensive, ready-to-install solutions for commercial vehicles.

- All-in-one kits with king pin, bearings, bushings, seals and all installation materials.

- No missing parts—everything needed is included

- Saves time and costs with smooth, efficient repairs

King pins engineered for tough roads, and designed to keep your fleet moving.

- Reliable OE-Matching Quality – Precision-engineered king pin ‘Made in Germany’ and all installation components (bushings, seals, etc.) perfectly matched for fast, reliable and lasting repairs.

- Maximum Vehicle Uptime – Durable king pins reduce wear and prevent unexpected breakdowns, keeping your fleet on the move.

- Fast & Easy Availability – With a wide range of more than 140 king pin sets for the European ‘BIG 8’ febi provides quick access to the right parts for all major truck brands.

More than140 King Pin Sets assembled as complete febi ProKits, ensuring you have everything needed for a seamless and efficient repair.

- Cost-Effective Repairs – febi ProKits include all necessary components in one box, such as bearings, bushings, seals, and all necessary installation materials.

- Easy Installation & Precision Fit – OE-matching precision ensures smooth repairs, reducing labor time and effort.

- Trusted German Engineering – Manufactured in-house with state-of-theart CNC technology in all production steps for consistent quality and durability.

King pins engineered for tough roads, and designed to keep your fleet moving.

- Reliable OE-Matching Quality – Precision-engineered king pin ‘Made in Germany’ and all installation components (bushings, seals, etc.) perfectly matched for fast, reliable and lasting repairs.

- Maximum Vehicle Uptime – Durable king pins reduce wear and prevent unexpected breakdowns, keeping your fleet on the move.

- Fast & Easy Availability – With a wide range of more than 140 king pin sets for the European ‘BIG 8’ febi provides quick access to the right parts for all major truck brands.

More than140 King Pin Sets assembled as complete febi ProKits, ensuring you have everything needed for a seamless and efficient repair.

- Cost-Effective Repairs – febi ProKits include all necessary components in one box, such as bearings, bushings, seals, and all necessary installation materials.

- Easy Installation & Precision Fit – OE-matching precision ensures smooth repairs, reducing labor time and effort.

- Trusted German Engineering – Manufactured in-house with state-of-theart CNC technology in all production steps for consistent quality and durability.

Your Benefits

Competitive Range

More than 2,300 steering and suspension parts - one of the widest ranges in the IAM - for the most important European manufacturers (the 'BIG 8').

Precise Fit

Designed and manufactured to assure absolute accuracy of fit, durability and longevity.

Time Saving

Numerous 'Complete Repair' parts package kits available for efficient and cost effective repairs.

Going Further

More Product Highlights in our continuously expanding range.

Steering Damper

- OE-matching quality guaranteed

- Exact dimensions for easy installation and reliable functionality

- Premium surface coating prevents rust to ensure long life

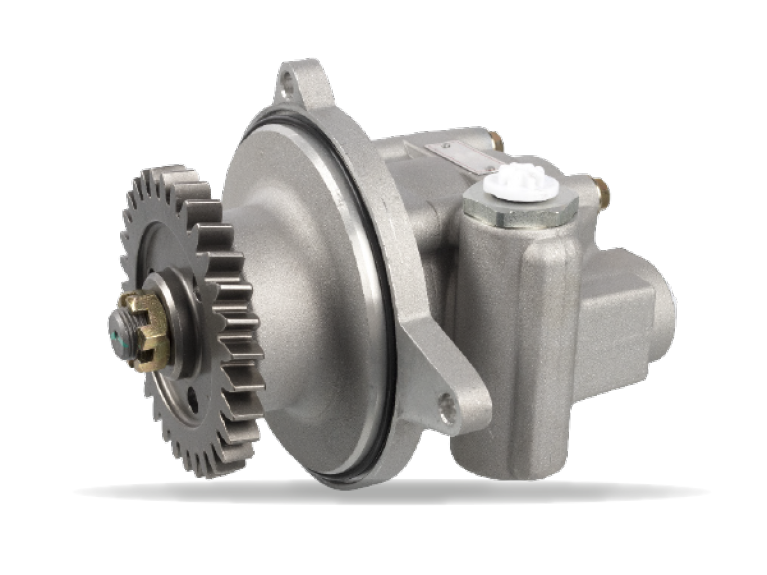

Power Steering Pumps

- One of the largest ranges of power steering pumps in the Independent Aftermarket

- Precise manufacturing for efficient pump operation

- High-quality materials ensure low wear and contribute to a long service life

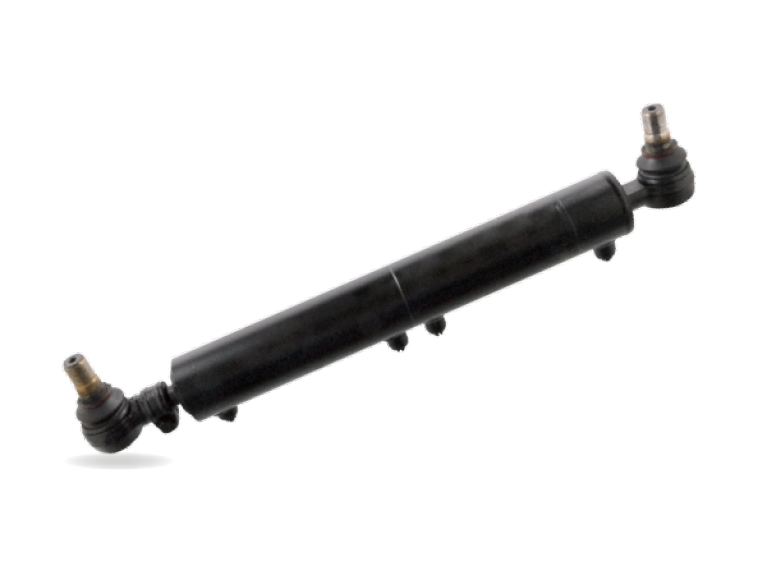

Working Cylinder for Steering

- Capable of withstanding pressures of up to 400 bar thanks to high quality materials and construction methods

- Always delivered complete with ball joints and all necessary fastening materials

- All ball joints are also available separately

Complete Solution

With ProKits febi has established innovative, complete repair solutions for all types of commercial vehicles!

- Complete parts sets perfectly tailored to specific requirements, containing everything needed for a successful service

- The all-in-ONE solution – everything you need in ONE package!

- Saves workshops money and time

Get the febi Newsletter