Quality from the Heart

Engine Components

Find your febi Truck replacement part at partsfinder

Selected Products

Quality from the Heart

febi Engine Components

Consistent quality is vital when it comes to lubrication. febi offers a comprehensive range of engine lubrication products, all subject to certified quality management tests for different requirements and loads.

Your Benefits

Highest Quality

Designed with strict quality standards.

Precise Fit

Manufactured to assure an absolute accuracy of fit.

Efficiency

High wear protection and reliability.

Complete supply for the heart of the engine - Oil Pumps

Part of our range of oil pumps are manufactured in-house, while the others come courtesy of carefully chosen suppliers who we trust to constantly deliver products of the very highest quality. All febi oil pumps produce the exact pressure for each specific application – a critical factor in preventing engine damage.

- Precisely manufactured designs made of aluminium or cast steel ensure a precise fit and long life

- Every oil pump is tested for pressure, revolutions per minute and litre capacity - all under real operating conditions

- Complete Oil Pump Sets

Always check surrounding components:Oil Pump maintenance and repair

When replacing the oil pump, the accompanying components should also be tested for wear and correct function. When replacing an oil pump it is important that the pressure relief value is also exhanged for a new one.

febi offers complete Oil Pump Sets for various types of vehicles containing all the extra parts required for an easy and hassle-free repair.

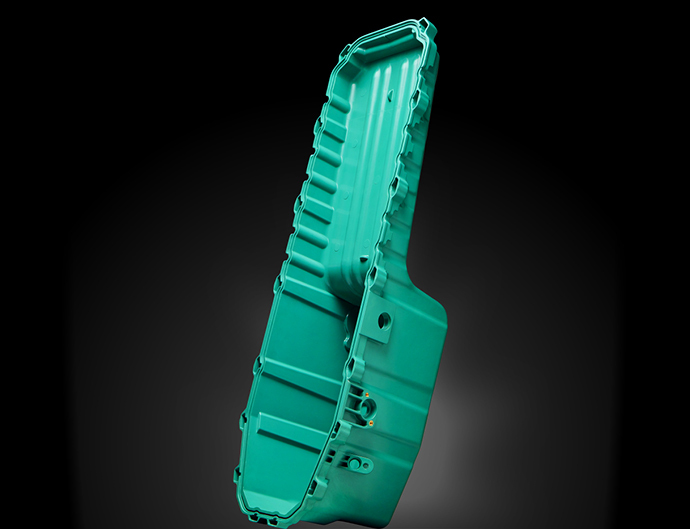

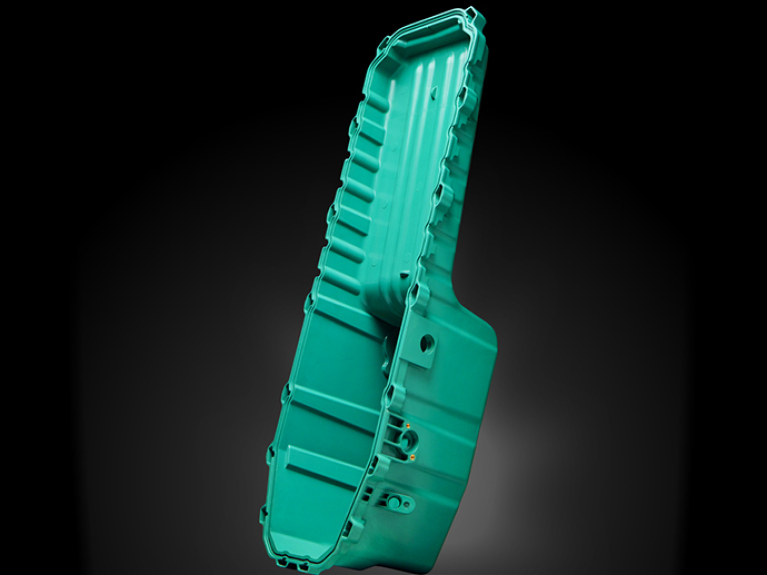

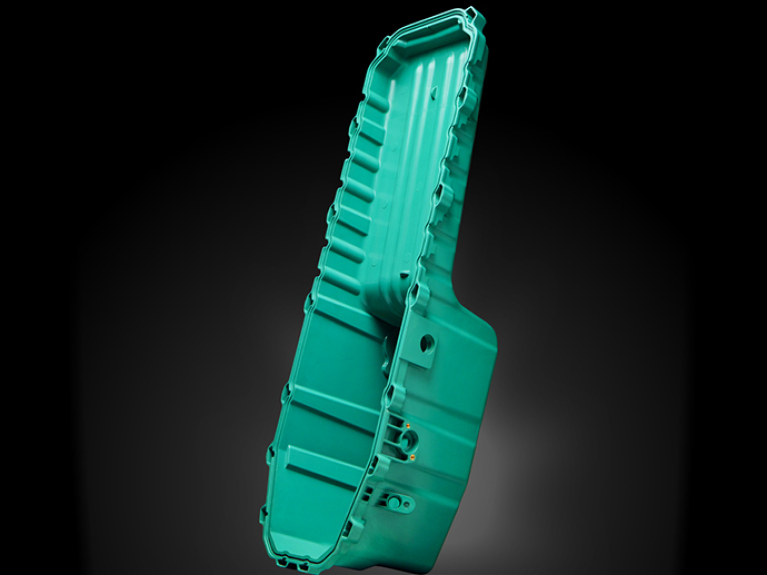

Weight Reduction and Fuel Savings Sump Pan

febi presents a brand-new product line for Volvo commercial vehicles fitted with plastic oil pans - covering a wide range of models with a single part number. In addition, we also offer the appropriate gasket for the engine to ensure consistent and even oil circulation.

- Plastic oil pans weigh approximately 60% less than those made of aluminium, saving fuel and thus helping reduce environmental impact

- Made from polyester resin with 30% glass fibre content according to OE-specification

Quality is CrucialOil Coolers

Oil coolers today consist of pressed aluminium plates manufactured in a layered arrangement. The oil can freely circulate between these individual plates without significant loss of pressure.

- Tested intensively by our certified quality management for different requirements and loads

- Tested for dimensional accuracy and material quality

Complete supply for the heart of the engine - Oil Pumps

Part of our range of oil pumps are manufactured in-house, while the others come courtesy of carefully chosen suppliers who we trust to constantly deliver products of the very highest quality. All febi oil pumps produce the exact pressure for each specific application – a critical factor in preventing engine damage.

- Precisely manufactured designs made of aluminium or cast steel ensure a precise fit and long life

- Every oil pump is tested for pressure, revolutions per minute and litre capacity - all under real operating conditions

- Complete Oil Pump Sets

Always check surrounding components:Oil Pump maintenance and repair

When replacing the oil pump, the accompanying components should also be tested for wear and correct function. When replacing an oil pump it is important that the pressure relief value is also exhanged for a new one.

febi offers complete Oil Pump Sets for various types of vehicles containing all the extra parts required for an easy and hassle-free repair.

Weight Reduction and Fuel Savings Sump Pan

febi presents a brand-new product line for Volvo commercial vehicles fitted with plastic oil pans - covering a wide range of models with a single part number. In addition, we also offer the appropriate gasket for the engine to ensure consistent and even oil circulation.

- Plastic oil pans weigh approximately 60% less than those made of aluminium, saving fuel and thus helping reduce environmental impact

- Made from polyester resin with 30% glass fibre content according to OE-specification

Quality is CrucialOil Coolers

Oil coolers today consist of pressed aluminium plates manufactured in a layered arrangement. The oil can freely circulate between these individual plates without significant loss of pressure.

- Tested intensively by our certified quality management for different requirements and loads

- Tested for dimensional accuracy and material quality

Get the febi Newsletter