Production Expertise

More Than a Parts Supplier

The Past, Today and in the Future

Ferdinand Bilstein carries over 50,000 different products in its product range – some come from selected partner producers, some from OE-suppliers. In addition, there are numerous proprietary articles: febi products – Made in Ennepetal.

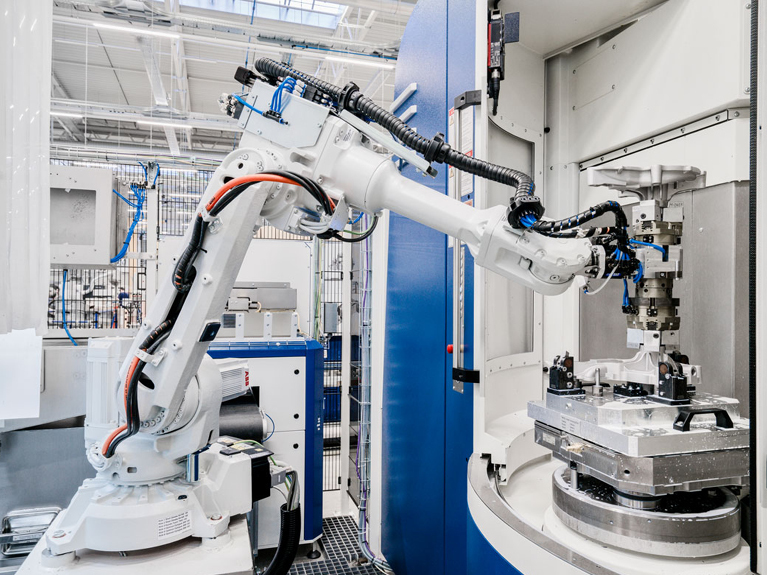

Ferdinand Bilstein has been active in the metal processing industry since 1844 and thus possesses lots of experience. In our in-house production - bilstein group Engineering - we manufacture various automotive parts – from chain tensioners to water and oil pumps to wheel hubs.

Our production area covers almost the entire production chain on 10,000 square metres: from toolmaking and machining to hardening, up to quality assurance with our own metrology room.

Compliance with the highest quality standards at every step is self-evident to us as a manufacturer.

Our Production Focus

Passenger vehicles

- Engine components (oil pump etc.)

- Transmission parts

- Suspension parts (transverse control arm, longitudinal control arm etc.)

Commercial vehicles

- Components for vehicle brakes

- Components for trailer couplings

- Components for vehicle superstructures

- Engine components (water pump, oil pump etc.)

Top Products

Made in Germany

For us, "Made in Germany" is both a demand and a quality promise at the same time.

We are constantly expanding our product range – we have thereby also significantly increased the share of our in-house parts.

In addition, we continually invest in the modernisation of our in-house production. The entire area was moved into a new, ultra-modern hall in 2017. Our machines are state-of-the-art and adapted and improved with a view to future requirements – with automation being a key word.

Our expertise in figures

130

More than 130 qualified employees

10000

over 10000 m² production area

70

More than 70 ultra-modern machines

175

About 175 years of experience in metalworking

The Quality Promise of our In-house Production

- 100% tested febi quality

- Made in Germany

- State of the art machinery

- Broad range of production

- Rate of skilled personnel >90%

Get the febi Newsletter